Dejian Zeng, a graduate student at New York University (NYU), got a job at Pegatron factory in China as part of a research project he is working on. Zeng worked with China Labor Watch to gather information about what it is like to work at one of the largest iPhone manufacturing plants in China. He spent six weeks as a plant worker for Pegatron and came back with a detailed experience of his time there.

Business Insider sat down with Zeng for a one-on-one interview and has published the transcripts of that conversation.

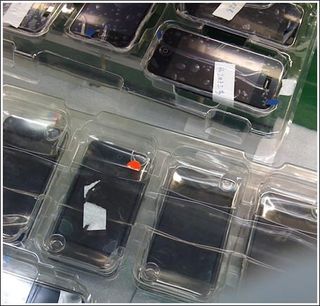

Zeng describes an average work day on the assembly line, which includes a lot of repetitive work (his first position was inserting one screw into the back case of an iPhone over and over again). It also includes very short breaks, strict security rules, and no phones allowed. That means no podcasts, no music, and nothing to stimulate the brain while working on mindless tasks.

Some other things of note in Zeng's research is that workers are required to wear a uniform provided by the company, but are only issued one uniform, employees get in trouble for laying down during breaks (not sleeping, but laying down), and day shift meals are more expensive than night shift meals.

Much of what Zeng uncovered is nothing that hasn't already been reported on dozens of times across the tech world, but hearing the level of detail about the daily life of an iPhone factory worker is fascinating, and a little hard to digest.

We just consider it a job that can give us money. Nobody enjoys the process, because the purpose of getting to work is waiting to get out. The only thing that we're thinking about is really money, money, money. I need to get some money from my family, I need to support my life, support my kids. That's the only thing in their mind. Sometimes they don't even care how tired they are.

There is always a level of scrutiny placed on companies, especially in the U.S. and especially major tech companies like Apple, for how they do business with manufacturers overseas. Apple has been transparent with how it handles labor practices in other countries by releasing a comprehensive progress report based on regular audits it conducts at supplier factories it works with.

At the same time, the current U.S. administration is pushing for companies to build factories and bring jobs into the country, instead of outsourcing. No one can honestly say that it wouldn't be great to have more jobs for skilled laborers in the U.S., but Zeng made an interesting point that we should all consider.

Master your iPhone in minutes

iMore offers spot-on advice and guidance from our team of experts, with decades of Apple device experience to lean on. Learn more with iMore!

From the labor perspective, I don't think it's very realistic for bringing labor-intensive manufacturers into the US. Why I'm saying that — just think about wages. Chinese people are getting 2320 yuan, which is about $400 per month. How much are you going to pay for the US workers in terms of base salary? If it really happened, if factories actually really moved to the US, I won't see it create a lot of jobs. I would see workers getting replaced by a lot of machines, because a lot of the work I see in the factory can actually be done by machine. The only reason why we do it is because the labor is even cheaper than the machine.

You can read the transcript of the entire interview at Business Insider.

Lory is a renaissance woman, writing news, reviews, and how-to guides for iMore. She also fancies herself a bit of a rock star in her town and spends too much time reading comic books. If she's not typing away at her keyboard, you can probably find her at Disneyland or watching Star Wars (or both).

Most Popular