Foxconn enforcing strict measures to keep iPhone manufacturing on track

What you need to know

- A Wall Street Journal report has revealed how Chinese factories are fending off the coronavirus post-lockdown.

- Government-mandated measures include wearing masks and checking temperatures, as well as filing daily reports on the health of each worker.

- Apple-supplier Foxconn has some of its own strict rules.

A Wall Street Journal report has revealed how factories in China are fighting coronavirus post lockdown, and has noted that Apple's iPhone manufacturer Foxconn has some of the strictest rules around.

According to the report:

Disinfect hands and shoes at the factory gate. Bring your own towel. No sunny-side-up eggs. Chinese companies are going to extreme lengths to stave off new outbreaks of the novel coronavirus as they reopen for business. It will be a crucial test of whether a country can keep the infection curve flat after lifting social distancing... Since businesses began reopening in February, China's State Council has required companies to supply employees with face masks and check everyone's temperature daily. Employers must submit daily reports on workers' health statuses, a system dubbed "One Person, One File."

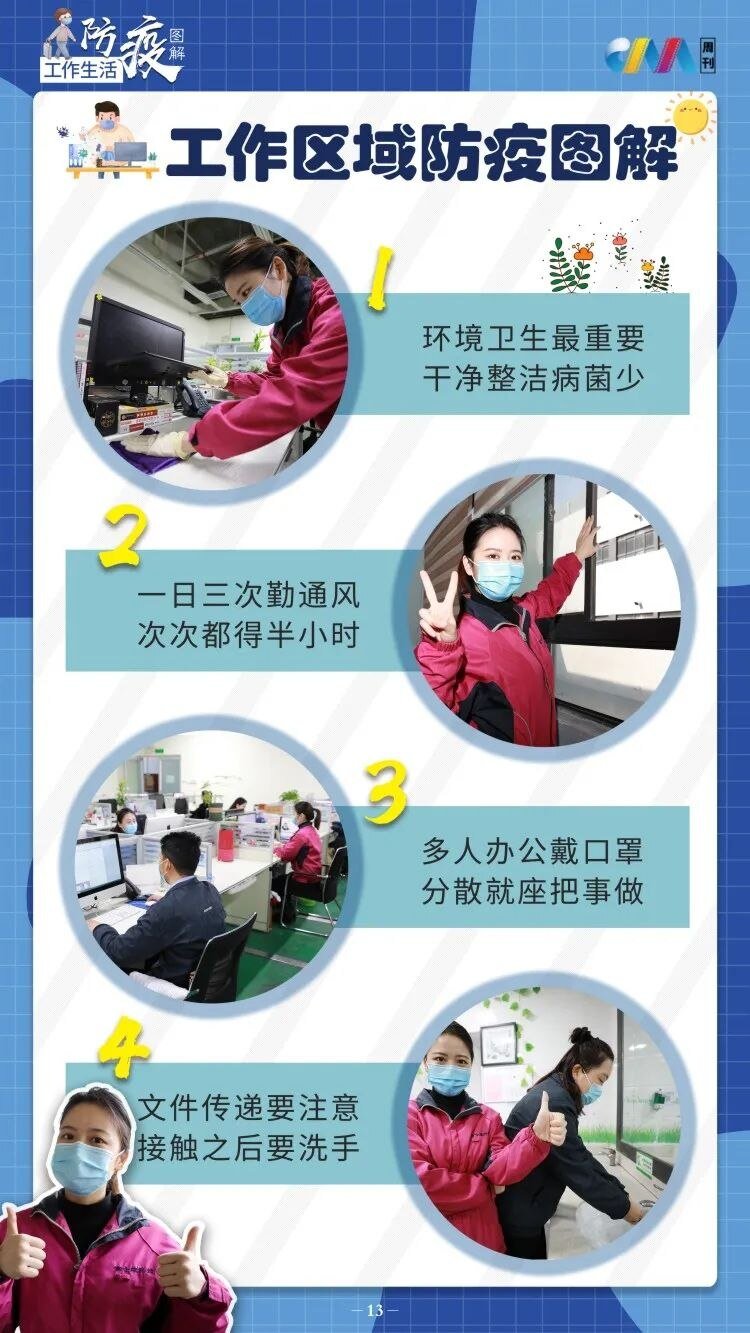

The report claims that production is going ahead in "semi-lockdown", with many workers not permitted to leave the campus without consent. Government-mandated measures also include opening office windows three times a day for 30 minutes, and the banning of fingerprint-entry keypads. Workers also cannot face each other whilst eating.

The below image is taken from a Foxconn manual, revealing some of the steps employees must take.

On Foxconn the report notes:

Companies have added their own rules. Some of the strictest are at manufacturers like iPhone assembler Foxconn Technology Group — China's largest private employer, with more than 1 million workers — which is anxious to keep on schedule for a fall iPhone launch. At Foxconn's iPhone-making complex in Zhengzhou, workers have been put into teams of 20 that stick together night and day to facilitate health tracking, according to a notice by the Zhengzhou government.

The factories' cafeterias have also been labelled with QR codes so that there is a full record of where everyone sits for their meals, worker coats and bags are also being disinfected, and temperatures are taken with infrared video cameras.

In a statement, Foxconn reportedly stated that it was using "all recommended health and hygiene practices" including nucleic acid tests and chest X-rays. A report at the end of March claimed Foxconn was still on track to launch the iPhone in the fall, despite some reports the 5G iPhone 12 may be delayed as a result of the pandemic.

iMore offers spot-on advice and guidance from our team of experts, with decades of Apple device experience to lean on. Learn more with iMore!

Stephen Warwick has written about Apple for five years at iMore and previously elsewhere. He covers all of iMore's latest breaking news regarding all of Apple's products and services, both hardware and software. Stephen has interviewed industry experts in a range of fields including finance, litigation, security, and more. He also specializes in curating and reviewing audio hardware and has experience beyond journalism in sound engineering, production, and design.

Before becoming a writer Stephen studied Ancient History at University and also worked at Apple for more than two years. Stephen is also a host on the iMore show, a weekly podcast recorded live that discusses the latest in breaking Apple news, as well as featuring fun trivia about all things Apple. Follow him on Twitter @stephenwarwick9